Measuring Tools for Engineers

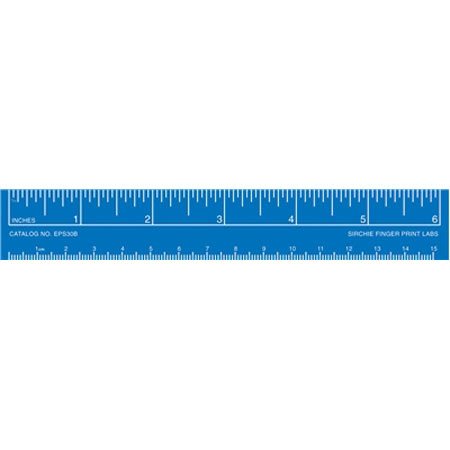

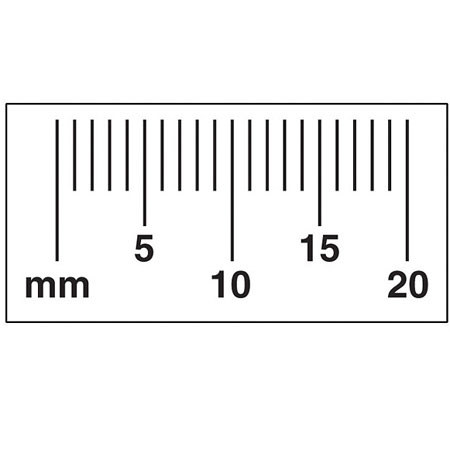

In the world of engineering, precision is everything. Whether on the shop floor, in a design lab, or out in the field, the ability to measure with accuracy and consistency forms the backbone of innovation and quality assurance. Engineering measurement tools are indispensable for professionals who demand reliable results—be it for constructing intricate prototypes, calibrating machinery, or verifying the integrity of manufactured parts. These tools span a broad spectrum, from the humble steel rule and tape measure to advanced digital calipers, micrometers, and laser distance meters. Each tool is designed with a specific purpose in mind: rulers and tapes for general linear measurements, squares and protractors for ensuring perfect angles, and specialized gauges for tasks where even a fraction of a millimeter matters. As winter settles in and projects shift indoors, there’s a renewed focus on detail-oriented tasks—making this the perfect season to upgrade or expand your collection of engineer measuring tools.

Selecting the right engineering measuring tools involves considering the nature of the work, the required precision, and the environment in which the tools will be used. For example, machinists and mechanical engineers often rely on micrometers and dial indicators to measure tiny tolerances, while civil engineers may prefer robust tape measures or laser measurers for surveying larger spaces. Those working in R&D or quality control departments benefit from height gauges and optical comparators, which are essential for detailed inspections and ensuring parts conform to stringent standards. Even hobbyists and students pursuing STEM fields find value in owning a set of calipers or a combination square—tools that not only build skills but also instill a respect for accuracy from the outset. These measuring instruments also make thoughtful gifts for aspiring engineers, recent graduates, or seasoned professionals looking to refresh their toolkits. There’s a particular satisfaction in unwrapping a finely crafted vernier caliper or a sleek digital protractor, knowing it will play a role in countless projects to come.

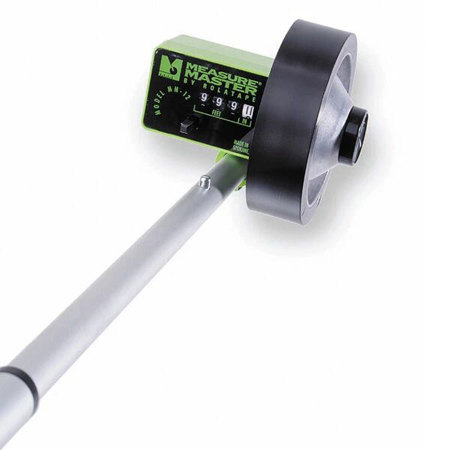

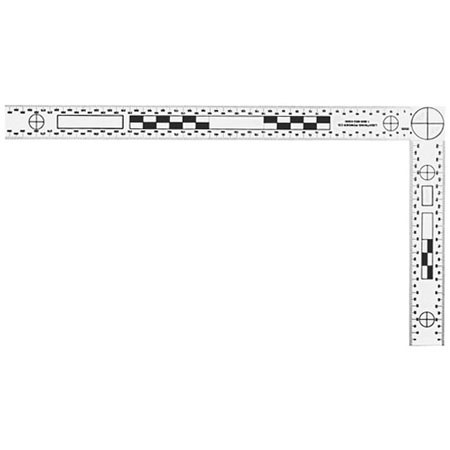

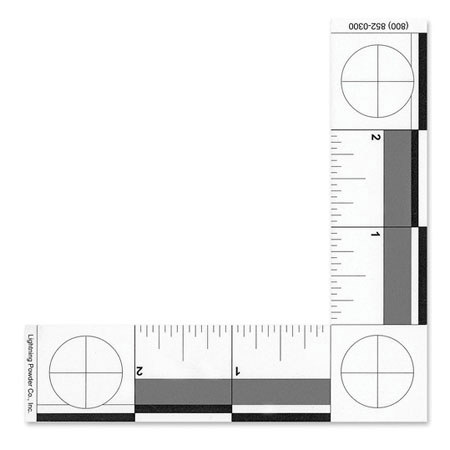

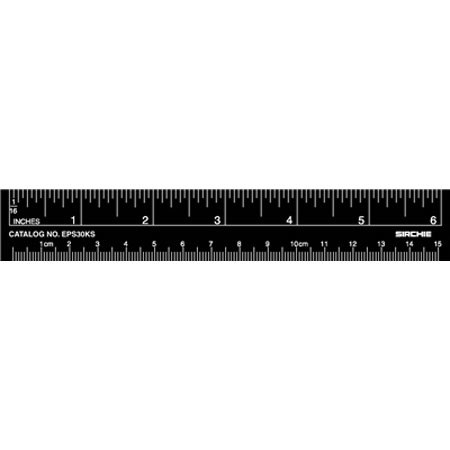

When building a toolkit, it’s important to match the tool to the task. For measuring shaft diameters or the thickness of sheet metal, a micrometer delivers unmatched precision. Calipers, on the other hand, are versatile workhorses—equally at home measuring internal and external dimensions or depths. For layout work or checking right angles, a sturdy engineer’s square or a bevel protractor is indispensable. In environments where speed and convenience are paramount, digital laser measures provide quick, accurate distance readings at the push of a button. And for those working with assemblies or engines, feeler gauges and depth gauges ensure that every clearance and recess is just right. As technology advances, many of these tools now feature digital displays, data output capabilities, and rugged construction to withstand harsh workshop conditions. For engineers whose work crosses into electrical systems or who collaborate with multidisciplinary teams, exploring specialized equipment such as those found on our Tools For Electrical Engineers page can further enhance your measurement capabilities. Investing in high-quality engineering measuring tools is more than a matter of convenience—it’s a commitment to craftsmanship, accuracy, and the enduring satisfaction of a job done right.

Selecting the right engineering measuring tools involves considering the nature of the work, the required precision, and the environment in which the tools will be used. For example, machinists and mechanical engineers often rely on micrometers and dial indicators to measure tiny tolerances, while civil engineers may prefer robust tape measures or laser measurers for surveying larger spaces. Those working in R&D or quality control departments benefit from height gauges and optical comparators, which are essential for detailed inspections and ensuring parts conform to stringent standards. Even hobbyists and students pursuing STEM fields find value in owning a set of calipers or a combination square—tools that not only build skills but also instill a respect for accuracy from the outset. These measuring instruments also make thoughtful gifts for aspiring engineers, recent graduates, or seasoned professionals looking to refresh their toolkits. There’s a particular satisfaction in unwrapping a finely crafted vernier caliper or a sleek digital protractor, knowing it will play a role in countless projects to come.

When building a toolkit, it’s important to match the tool to the task. For measuring shaft diameters or the thickness of sheet metal, a micrometer delivers unmatched precision. Calipers, on the other hand, are versatile workhorses—equally at home measuring internal and external dimensions or depths. For layout work or checking right angles, a sturdy engineer’s square or a bevel protractor is indispensable. In environments where speed and convenience are paramount, digital laser measures provide quick, accurate distance readings at the push of a button. And for those working with assemblies or engines, feeler gauges and depth gauges ensure that every clearance and recess is just right. As technology advances, many of these tools now feature digital displays, data output capabilities, and rugged construction to withstand harsh workshop conditions. For engineers whose work crosses into electrical systems or who collaborate with multidisciplinary teams, exploring specialized equipment such as those found on our Tools For Electrical Engineers page can further enhance your measurement capabilities. Investing in high-quality engineering measuring tools is more than a matter of convenience—it’s a commitment to craftsmanship, accuracy, and the enduring satisfaction of a job done right.