Wire Assemblies

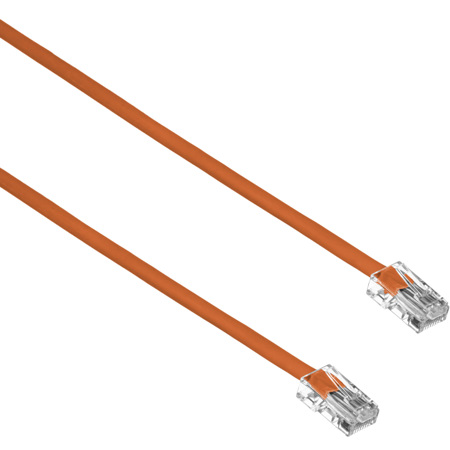

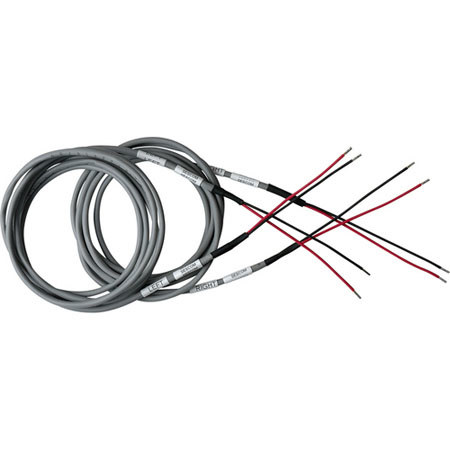

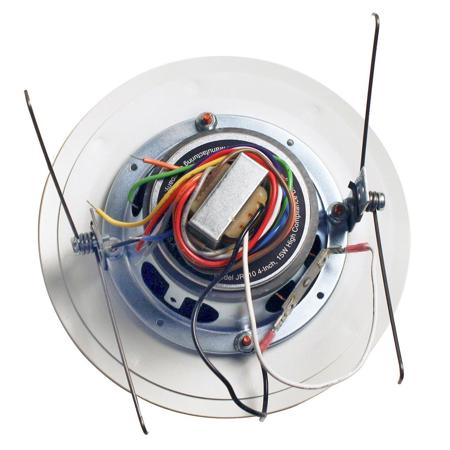

Wire assemblies, often referred to as wire harnesses, are the backbone of modern electrical systems, seamlessly channeling power, data, and signals between components in a way that is both efficient and secure. These assemblies are meticulously designed to meet the specific requirements of each application, whether they’re destined for a cutting-edge audio production studio, a bustling automotive repair shop, or a medical device manufacturer’s cleanroom. Each wire assembly brings together a carefully selected bundle of wires and cables, integrating connectors, terminals, and protective sleeves to ensure not only reliable connectivity, but also long-term durability in challenging environments. The transition from summer to fall is a busy time for many industries, as new projects ramp up and existing systems are upgraded for the coming year, making it an ideal season to evaluate and refresh your stock of wire assemblies. Whether you’re setting up a new rack of lighting equipment for autumn events, upgrading the wiring in a custom PC build, or preparing an industrial automation system for increased production demands, having the right wire assembly can make all the difference in performance and safety.

When choosing wire assemblies, several key considerations come into play. The first is organization: by bundling wires together in a single harness, you can greatly reduce clutter and tangling, which not only streamlines installation but also enhances ongoing maintenance and troubleshooting. Protective features such as sleeves, heat shrink tubing, and conduit shield the wires from dust, moisture, and mechanical stress—an essential safeguard in environments where vibration, movement, or temperature fluctuations are common. The integrated connectors and terminals are selected for compatibility with your devices, ensuring a secure, ready-to-use connection that minimizes the risk of electrical faults or intermittent failures. For those working in audio/video production, wire assemblies are vital for keeping signal paths clear and interference-free, while in the world of robotics and industrial automation, they provide the reliable power and data transmission needed to keep complex systems running smoothly. If you’re assembling or repairing electronics, the right wire assembly can transform a tangled mess of individual wires into a neatly routed, easily managed solution that not only looks professional but also optimizes space and airflow within your equipment.

Wire assemblies aren’t just the domain of engineers and technicians—they also make thoughtful, practical gifts for anyone who loves to tinker, build, or upgrade their own gear. Imagine the satisfaction of unwrapping a custom wire harness that perfectly fits a beloved vintage amplifier, or the convenience of receiving a pre-assembled cable set for a home recording studio just as the creative season kicks off. Because each assembly is tailored to its intended use, you’ll want to consider factors like wire gauge, insulation type, and connector compatibility; for those seeking more information on sizing and selection, our guide to AWG Cables is an invaluable resource. Rigorous testing—covering everything from continuity and pull strength to environmental resistance—ensures that every wire assembly delivers the reliability and performance demanded by today’s professionals and hobbyists alike. As you look ahead to new projects this fall, investing in high-quality wire assemblies is a smart way to safeguard your equipment, streamline your workflow, and ensure that every connection in your system is as robust and dependable as the work you do.

When choosing wire assemblies, several key considerations come into play. The first is organization: by bundling wires together in a single harness, you can greatly reduce clutter and tangling, which not only streamlines installation but also enhances ongoing maintenance and troubleshooting. Protective features such as sleeves, heat shrink tubing, and conduit shield the wires from dust, moisture, and mechanical stress—an essential safeguard in environments where vibration, movement, or temperature fluctuations are common. The integrated connectors and terminals are selected for compatibility with your devices, ensuring a secure, ready-to-use connection that minimizes the risk of electrical faults or intermittent failures. For those working in audio/video production, wire assemblies are vital for keeping signal paths clear and interference-free, while in the world of robotics and industrial automation, they provide the reliable power and data transmission needed to keep complex systems running smoothly. If you’re assembling or repairing electronics, the right wire assembly can transform a tangled mess of individual wires into a neatly routed, easily managed solution that not only looks professional but also optimizes space and airflow within your equipment.

Wire assemblies aren’t just the domain of engineers and technicians—they also make thoughtful, practical gifts for anyone who loves to tinker, build, or upgrade their own gear. Imagine the satisfaction of unwrapping a custom wire harness that perfectly fits a beloved vintage amplifier, or the convenience of receiving a pre-assembled cable set for a home recording studio just as the creative season kicks off. Because each assembly is tailored to its intended use, you’ll want to consider factors like wire gauge, insulation type, and connector compatibility; for those seeking more information on sizing and selection, our guide to AWG Cables is an invaluable resource. Rigorous testing—covering everything from continuity and pull strength to environmental resistance—ensures that every wire assembly delivers the reliability and performance demanded by today’s professionals and hobbyists alike. As you look ahead to new projects this fall, investing in high-quality wire assemblies is a smart way to safeguard your equipment, streamline your workflow, and ensure that every connection in your system is as robust and dependable as the work you do.