Bullet Moulds

For enthusiasts who take pride in crafting their own ammunition, bullet moulds are an essential addition to any reloading setup. The process of bullet molding is both an art and a science, offering a satisfying level of control over the components that go into each round. Whether you’re an experienced handloader or just beginning to explore the world of custom ammunition, the right bullet mould opens a world of possibilities. The winter months, when outdoor shooting may be less frequent, are the perfect time to focus on reloading and refining your technique in the warmth of your workshop. Many shooters use this season to stock up on hand-cast bullets, experimenting with different alloys and mould types to achieve the perfect balance of accuracy, expansion, and reliability. For those who appreciate the tactile satisfaction of pouring molten lead into a sturdy mould, watching the metal cool and solidify, and then admiring a tray of freshly cast projectiles, there’s nothing quite like the sense of accomplishment that comes with each batch.

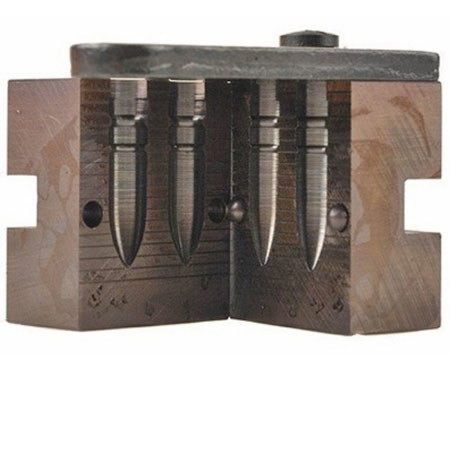

Selecting the right bullet mould depends on a variety of factors, from the caliber and bullet style to the intended use. Precision shooters, hunters, and hobbyists all have unique requirements, whether they’re casting classic round-nose bullets for target practice or opting for a 9mm hollow point bullet mold to produce rounds with enhanced expansion for personal defense. Custom bullet molds allow for fine-tuning bullet weight and profile, catering to specific firearms or shooting disciplines. Some moulds, like the 662 bullet design, are favored for their versatility and proven performance across a range of applications. When considering a bullet mould, pay attention to the number of cavities—single-cavity moulds offer meticulous attention to detail, while multi-cavity options increase production speed for those looking to cast in volume. Material matters, too; iron, aluminum, and brass each have their champions, with differences in heat retention, durability, and ease of maintenance. For newcomers, investing in quality handles and a reliable lead pot will make the process smoother and safer, while seasoned reloaders might appreciate experimenting with custom designs or specialty shapes to optimize their loads.

Bullet moulds also make thoughtful gifts for reloaders and shooting sports enthusiasts. There’s a special camaraderie among those who share casting tips, swap alloy recipes, or gather for winter reloading sessions. Gifting a high-quality mould can inspire a new hobby or help a friend fine-tune their favorite load. For those who reload 9mm, pairing a mould with a set of 9mm Pistol Reloading Dies creates a comprehensive kit for both casting and finishing rounds, making it a practical and appreciated gesture. Whether you’re preparing for the next competition season, building up a reserve for spring range days, or simply enjoying the meditative process of bullet casting, the right bullet mould is a tool that delivers satisfaction with every pour. The journey from raw lead to finished ammunition is one of skill, patience, and tradition—a rewarding pursuit that connects generations of shooters and craftsmen.

Selecting the right bullet mould depends on a variety of factors, from the caliber and bullet style to the intended use. Precision shooters, hunters, and hobbyists all have unique requirements, whether they’re casting classic round-nose bullets for target practice or opting for a 9mm hollow point bullet mold to produce rounds with enhanced expansion for personal defense. Custom bullet molds allow for fine-tuning bullet weight and profile, catering to specific firearms or shooting disciplines. Some moulds, like the 662 bullet design, are favored for their versatility and proven performance across a range of applications. When considering a bullet mould, pay attention to the number of cavities—single-cavity moulds offer meticulous attention to detail, while multi-cavity options increase production speed for those looking to cast in volume. Material matters, too; iron, aluminum, and brass each have their champions, with differences in heat retention, durability, and ease of maintenance. For newcomers, investing in quality handles and a reliable lead pot will make the process smoother and safer, while seasoned reloaders might appreciate experimenting with custom designs or specialty shapes to optimize their loads.

Bullet moulds also make thoughtful gifts for reloaders and shooting sports enthusiasts. There’s a special camaraderie among those who share casting tips, swap alloy recipes, or gather for winter reloading sessions. Gifting a high-quality mould can inspire a new hobby or help a friend fine-tune their favorite load. For those who reload 9mm, pairing a mould with a set of 9mm Pistol Reloading Dies creates a comprehensive kit for both casting and finishing rounds, making it a practical and appreciated gesture. Whether you’re preparing for the next competition season, building up a reserve for spring range days, or simply enjoying the meditative process of bullet casting, the right bullet mould is a tool that delivers satisfaction with every pour. The journey from raw lead to finished ammunition is one of skill, patience, and tradition—a rewarding pursuit that connects generations of shooters and craftsmen.