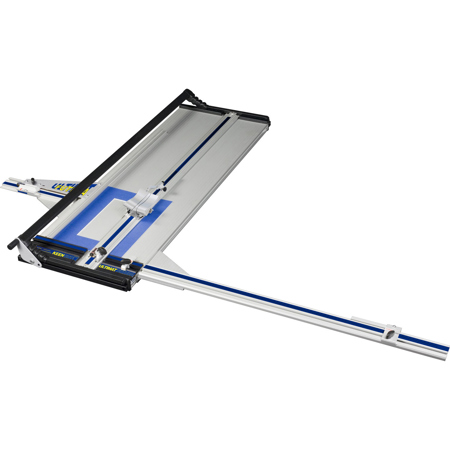

Keencut 40" Ultimat Futura Mat Cutter

This item is no longer available.

Questions & Answers

Reviews about this item

Review Summary

Select a plan in the Add Protection section above and purchase with this product by clicking “Add to Cart”.

TRUSTED PROTECTION PLANS, EXCEPTIONAL SERVICE.

Invest In Your Gear and Peace Of Mind!

Accidents happen. Protect your favorite Adorama products and purchase a protection plan to stay covered from accidental damage, mechanical or electrical failures, and more.

Repair or Replacement

If we can’t fix it, we’ll replace it at no additional cost.

Accidental Damage

Protect your product from drops, spills, and more.

Peace of Mind

Enjoy your gear without fear. We have you covered!

Failure Protection

When regular use of your product over time results in mechanical or electrical failure.

Zero Deductible

We will never charge you a deductible after the purchase of a plan.

Customer-Focused Support

Our claims process is simple & easy and our customer service team is happy to help.

Adorama Protect powered by Extend is available for purchase to customers in the United States. Not available for international or U.S. territories purchases. Plans on open box items do not cover pre-existing damage.

Adorama Protect plans are available for ABS clients. If you have any questions or require assistanse, please call 800-223-2500

Browse our FAQ

Keencut Ultimat Futura Specifications

Dimensions

47 x 40 x 15.5" (119.38 x 101.60 x 39.37cm)

About Keencut Ultimat Futura

Keencut Ultimat Futura builds on the unique versatility, advanced design and precision of the world leading Ultimat Gold to take manual Mount Cutting to an ultra-high level of accurate, fast operation on all modern mount board of every type and thickness. The Ultimat Futura Mount Cutter features an all-new cutting head with built-in self-aligning ball bearing rollers operating on twin steel tracks to deliver a sliding action that is smooth, precise and with no discernible friction under load. Maximum operator effort is transmitted to the blade to put the cutting of even 8ply mount board within the capability of every framer.

• All new cutting head

• Unique patented 'micro-stop' adjusters

• Unique roller 'lift and hold' system

• Unique base clip system

• Unique start-of-cut finger

• Removable squaring arm

• High performance steel roller bearings

• Bevel & vertical cutting head features

• Optional multi-angle cutting gauges

• Optional 75cm extension mat guide kit

• Optional support arms, 60cm long

Switchable magnetic blade holders on the Ultimat Futura make changing blades and holders for different depths of cut the simple, fast operation so necessary for the many different types of work that are processed in every busy framing workshop and the ergonomically designed cutting head is comfortable for left or right-handed operation.

Starting with the best and improving on it was a logical step and the winning features of the Ultimat Gold have been retained for the Futura including the roller 'lift and hold' system, patented micro-stops and uniquely designed baseplate to accept a range of readily available accessories. The new high performance slideway and head system has been designed in response to the latest and future mount board developments and will not only maintain but greatly increase the Keencut world leadership in manual mat cutter design. The good news for any current owner of the original Ultimat or Ultimat Gold is that the Futura slideway, cutting head and stop system have been specifically designed to retro-fit to existing machines.

Outstanding Features Of The Ultimat Futura

• Designed specifically for ultra-high accuracy & fast operation on all modern mat board of every type and thickness

• Features an All-New cutting head with built-in self-aligning ball bearing rollers operating on twin steel tracks designed to give a lifetime of straight, accurate, silent cutting

• New cutting head delivers a sliding action that is smooth, precise and with no discernible friction under load

• Maximum operator effort is transmitted to the blade to put the cutting of even 8ply mount board within the capability of every framer

• Switchable magnetic blade holders makes changing blades and holders for different depths of cut simple and fast

• Supplied as standard with 2 Bevel Blade Holders and 1 Vertical Blade Holder

• Additional Blade Holders are available if users want to switch between various board thicknesses quickly and avoid making depth adjustments

• Ergonomically designed cutting head is comfortable for left or right-handed operation

• Uniquely designed baseplate accepts a range of readily available accessories

• The new high performance slideway and head system has been designed in response to the latest and future mount board developments and will not only maintain but greatly increase the Keencut world leadership in manual mat cutter design

• Unique sliding gauge pinpoints blade entry and exit spot for exact freehand cutting

• The unique one piece solid end frame is set perfectly square in the factory with a single adjustment screw

• The instant clip-on clip-off right squaring arm with repetition stop is provided to accurately size all mat boards from 90cm (36") down to 4cm (1.5")

• V-groove stop with micro scale

• Unique 'clip on' margin guide and squaring arm allows for easy removal when not in use; no tools required. Maximum standard margin width is 19cm (7.5")

• The rigid T-bar mat guide is extendable up to 75cm (30") using the Mat guide Extension Kit giving accurate all-round location for the title box and multiple aperture cutting.

• Instantly removable when cutting large boards down to size

• Margin guide easily un-clips for those users wishing to free-hand cut margins greater than 19cm

Ease Of Operation & Safety Features

• Spring loaded bevel and vertical blade holder featuring ball and thrust bearings for perfect alignment and superb blade control

• Vertical blade may be locked in the up position for safety, locked down for convenience when cutting regular board or depressed progressively against a light spring to effortlessly cut through very thick board or multiple sheets with a number of passes

• Unique patented micro stop adjusters fitted to the 'start of cut,' 'end of cut' and 'margin guide' stops allow you to dial out overcuts or undercuts in seconds

• Excellent control stops have always been a feature of Keencut machines. Unique to the Ultimat Gold and Ultimat Futura the routine stop adjustments for different thicknesses of board are reduced to just two

• The start and end of cut stops can be reset in seconds. Any overcut is eliminated by turning the stop thumbscrew towards minus. Any undercut is eliminated by turning the thumbscrew towards plus. Nothing could be more simple or precise

• The unique spring loaded measuring stop slides with the cutting head

• When the start-of-cut finger is depressed to make contact with the mat edge it precisely controls distance from the edge of the mat to the blade tip

• When cutting mats large or small, square or rectangular the stop does not need to be reset

• When set to zero the stop will precisely indicate the start and stop points of the blade when cutting multiple openings or special effects that have been laid out with pencil lines

• The extra slim cutter bar is only 6.2cm (2.44") wide with a full length gripper strip which makes cutting miniatures simple and tightly secures the largest mats with no hand pressure

• Unlike other mat cutters it is not necessary to apply any pressure to the handle whilst the machine is in operation. This is due to the carefully balanced slideway which ensures even contact and clamping. No holding of the handle means both hands are free for easy operation of the machine

• Unique roller 'lift and hold' system raises or lowers the cutter bar and frees both hands

• Operates in one smooth and silent movement and when used as the alternative to the main handle reduces the already low lifting effort by two thirds for easy all day working

• Frees both hands for mat handling and makes routine setting and working a pleasure

• Unique Base Clip System: Margin guide, squaring arm and optional board support are instantly removable for space saving or safety when the machine is not in use

Guarantees & Construction

• Pre-lubricated ball bearings on steel slide track for precision and low friction

• 100% manufactured by Keencut Technicians in England

• 99.98% of materials from the best suppliers in Western Europe

• High tensile aerospace aluminum alloy construction

• Super grade anodizing for lifetime good looks and function

• Designed specifically for the Professional Picture Framer

• 5 year comprehensive guarantee

• 20 year replacement guarantee on all slide bearings

What's in the box:

- Keencut 40 " Ultimat Futura Mat Cutter

- 30x Tech D .012 Blades

- 20x Superior Quality Utility Blades

- 15x Tech S .012 Blades

- 15x Tech S .015 Blades

- Keencut 5 Year Warranty